FRENIC MEGA

- Best vector control for the general-purpose inverter in the class

- Accommodating various applications

- Wide model variation meeting the customer needs

- Supports for simple maintenance

- Network building

Description

- Best vector control for the general-purpose inverter in the class

- Accommodating various applications

- Wide model variation meeting the customer needs

- Supports for simple maintenance

- Network building

- Prolonged service life and improved life judgment function

- Consideration for environment

- Global compatibility

- Function Safety

Best vector control for the general-purpose inverter in the class

Ideal for highly accurate control such as positioning

PG vector control

Effective in providing highly accurate control for applications such as printing press

Speed control range: 1:1500

Speed response: 100Hz

Speed control accuracy: ±0.01%

Current response: 500Hz

Torque accuracy: ±10%

* The option card is required separately.

* The above specifications may vary depending on the environment or conditions for use.

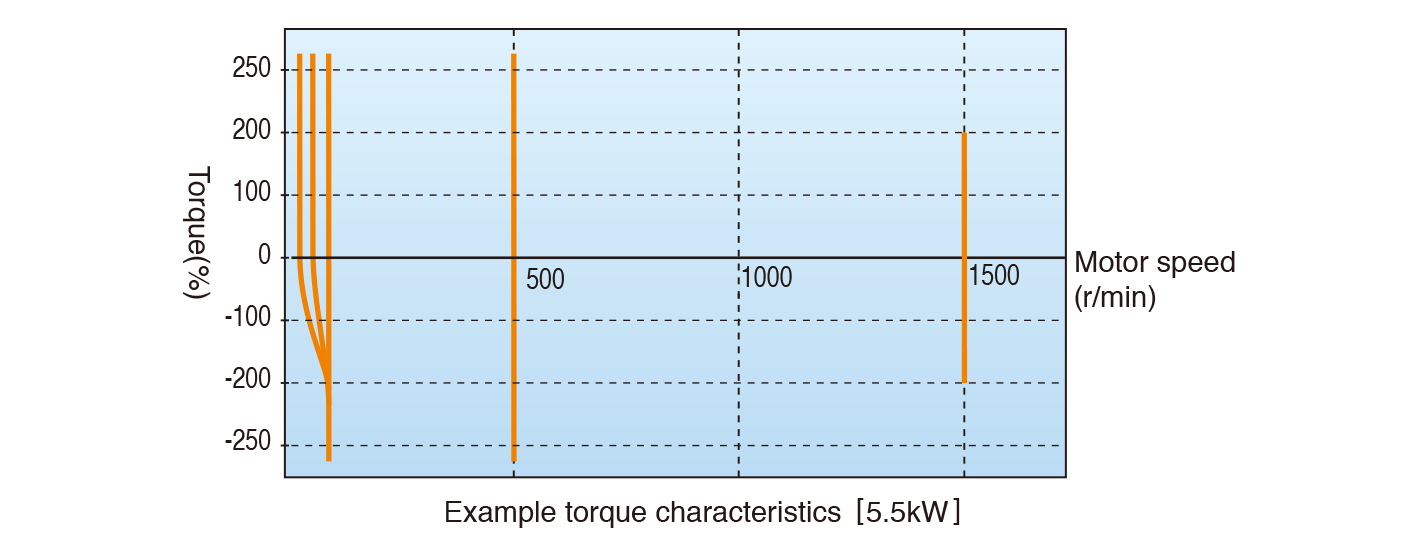

Fuji’s original dynamic torque vector control has further evolved.

Besides the dynamic torque vector control, the inverter is equipped with the motor constant tuning for compensating even a voltage error of the main circuit devices and the magnetic flux observer of a new system. This realizes a high starting torque of 200% even at a low-speed rotation of 0.3Hz.

Improved durability in overload operation

The inverter performs short-time acceleration and deceleration with the maximum capacity by extending the time specification of overload current ratings compared with our previous models. This improves the operation efficiency of the equipment such as cutting machine or conveyance machine.

Overload durability: 200% for 3 sec and 150% for 1 min.

The standard model is available in two specifications concerning the operation load.

| Classification | Overload current rating | Major use |

|---|---|---|

| HD (High duty) spec | 200% for 3 sec, 150% for 1 min | Operation under heavy load |

| MD (Middle duty) spec | 150% for 1 min | Operation under constant torque load |

| LD (Low duty) spec | 120% for 1 min | Operation under light load |

Expanded capacity for the braking circuit built-in type

A braking circuit is built in the 22kW or smaller models as standard. These inverters are applicable to the machine that uses regenerative load such as a vertical conveyance machine.

(The 7.5kW or smaller models also incorporate a braking resistor.)

* The inverters with built-in braking circuit are available on request for 30kW to 160kW models in 400V series.

Maximizing the performance of a general-purpose motor

Speed sensor-less vector control

Useful for the application that requires a high starting torque, such as the gondola type multi-level car parking tower

Speed control range: 1:200

Speed response: 20Hz

Speed control accuracy: ±0.5%

Current response: 500Hz

Torque accuracy: ±10%

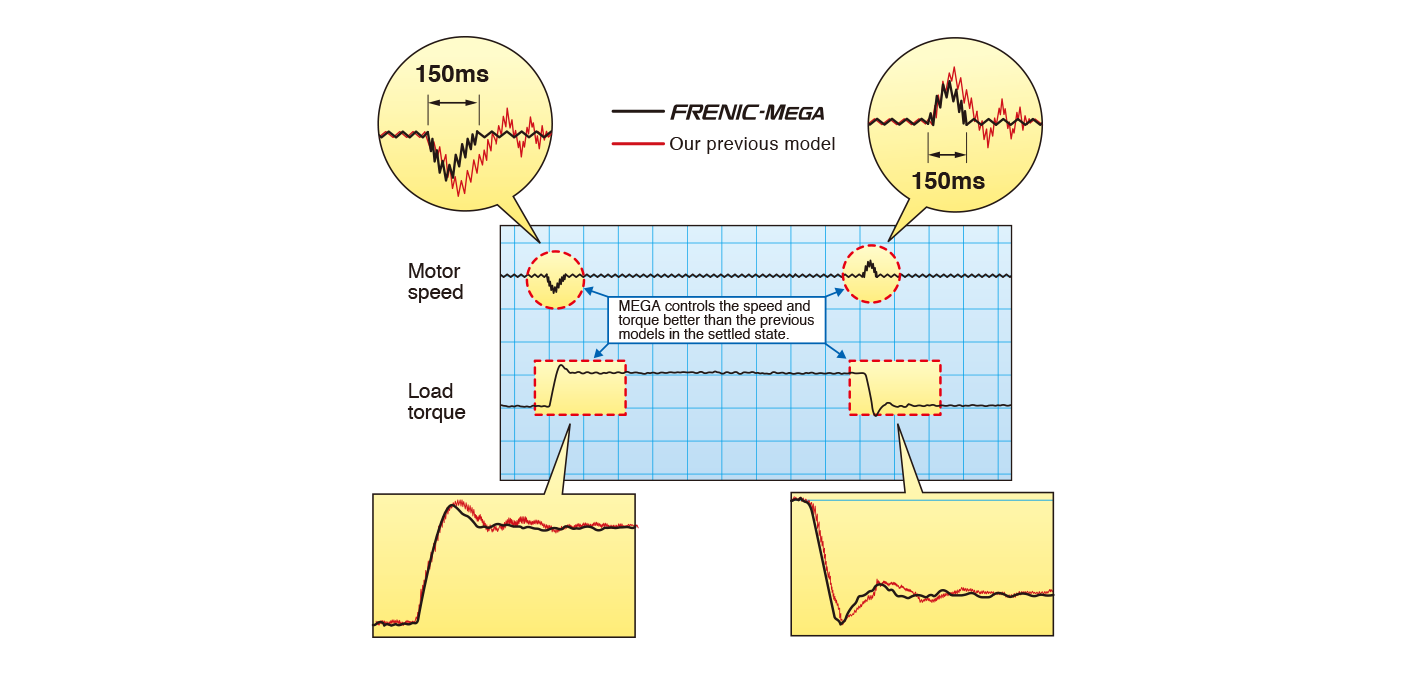

Improved reaction to the fluctuation of impact load

When a remarkable load fluctuation occurs, the inverter provides the torque response in the class-top level. It controls the flux to minimize the fluctuation in the motor speed while suppressing the vibration. This function is best suited for the equipment that requires stable speed such as a cutting machine.

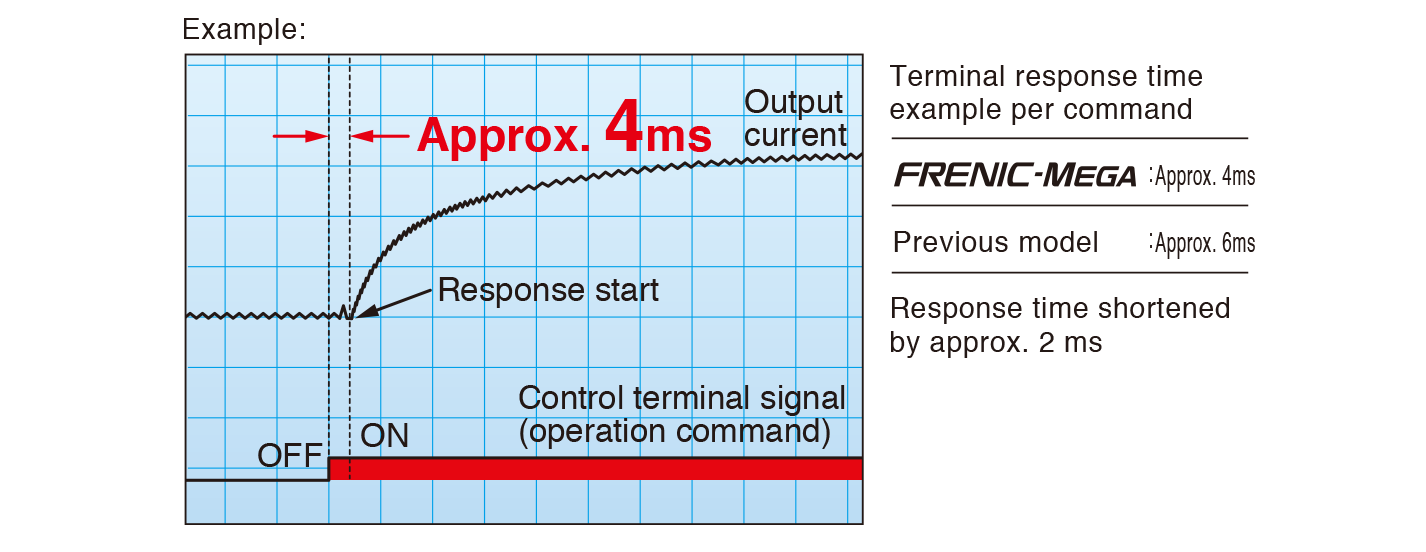

Quicker response to the operation commands

The terminal response to the operation commands has had an established reputation. FRENIC-MEGA has further shortened this response time, achieving the industry-top response time.

This function is effective in shortening the tact time per cycle and effective for use in the process including frequent repetitions.

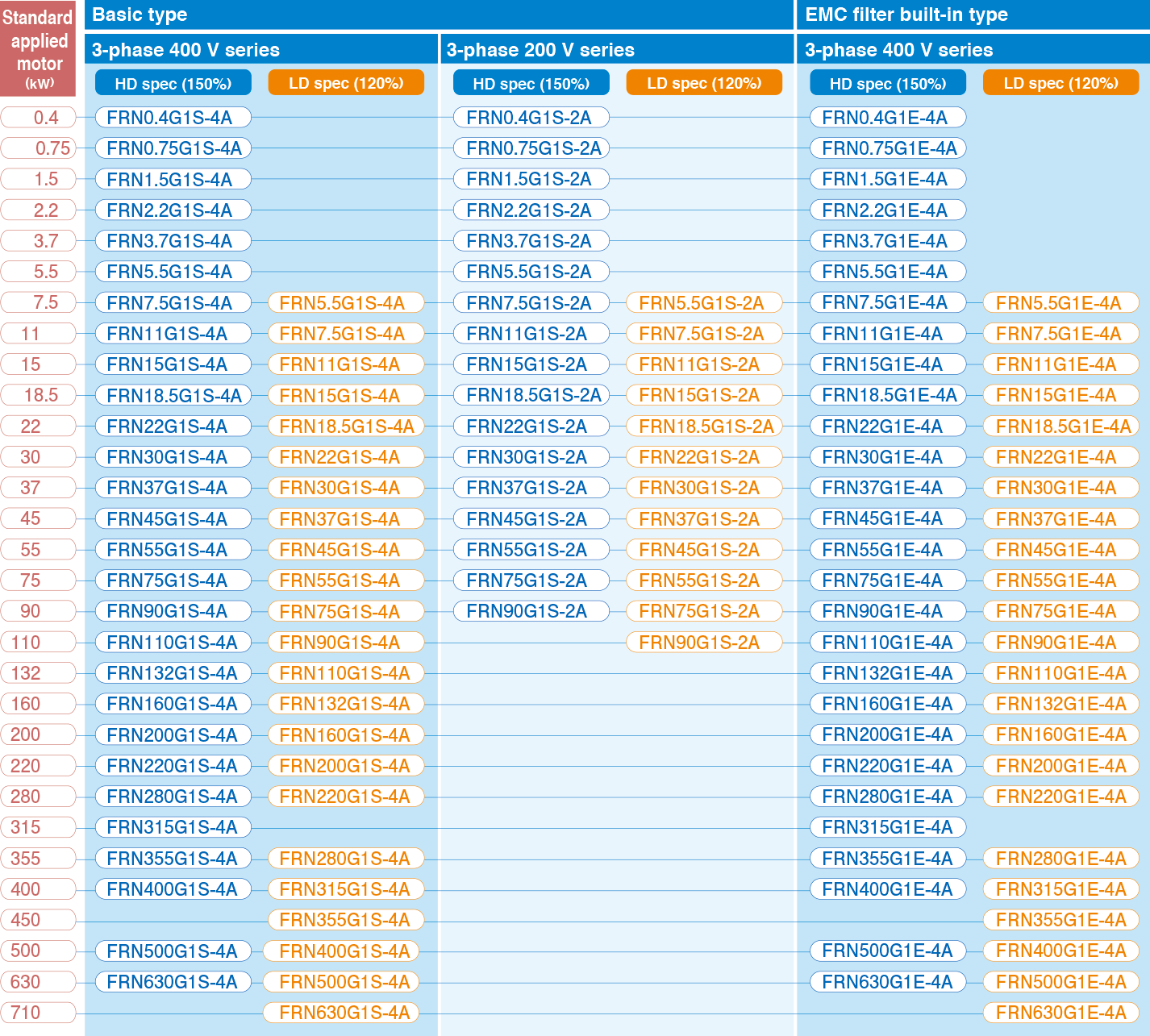

Variations

Model list

HD : High Duty spec 200% for 3 sec, 150% for 1min

LD : Low Duty spec 120% for 1 min

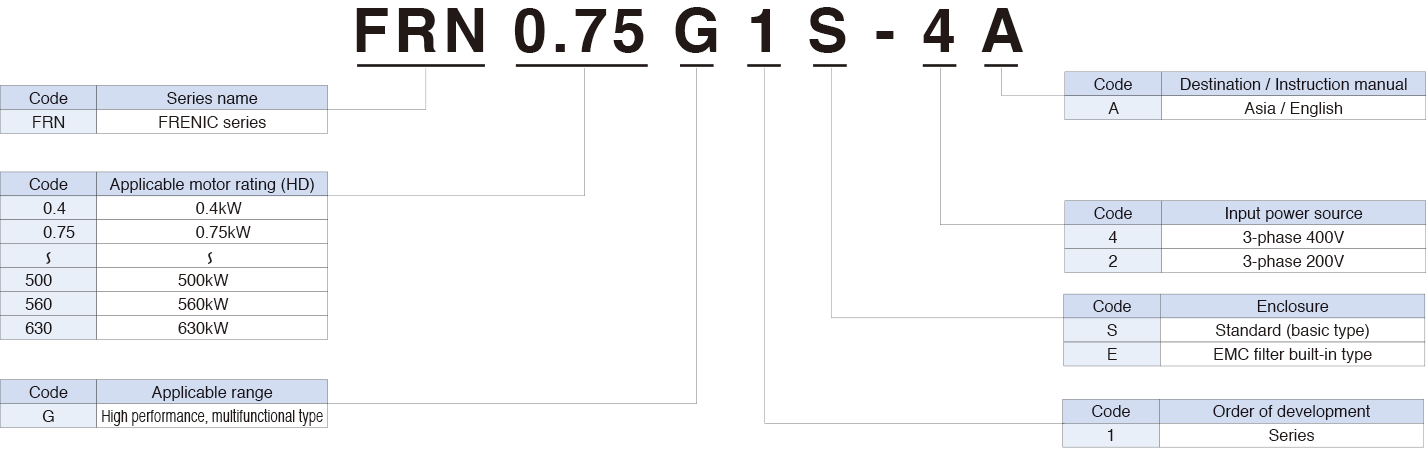

How to read the inverter model

*The keypad is not included as standard equipment for inverters. Please select and use either (1) multi-function keypad (TP-G1-J1) or (2) remote control keypad (TP-E1U) as option.

*The DC reactor is not included as standard equipment for inverters. Please select and use the optional DC reactor listed on page 46 in this catalog.

![]()

The contents of this catalog are provided to help you select the product model that is best for you. Before the actual use, be sure to read the User’s Manual thoroughly for proper operations.

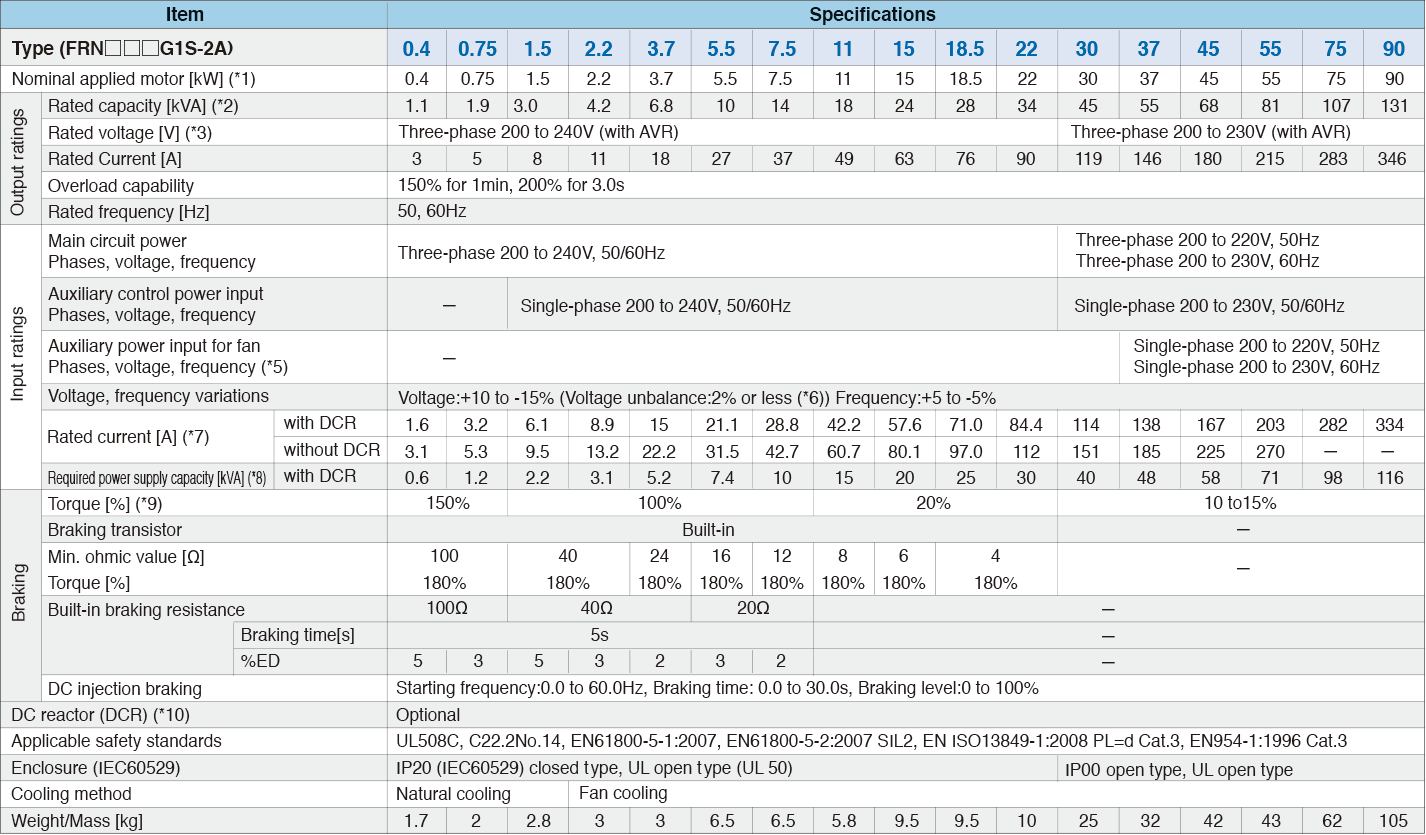

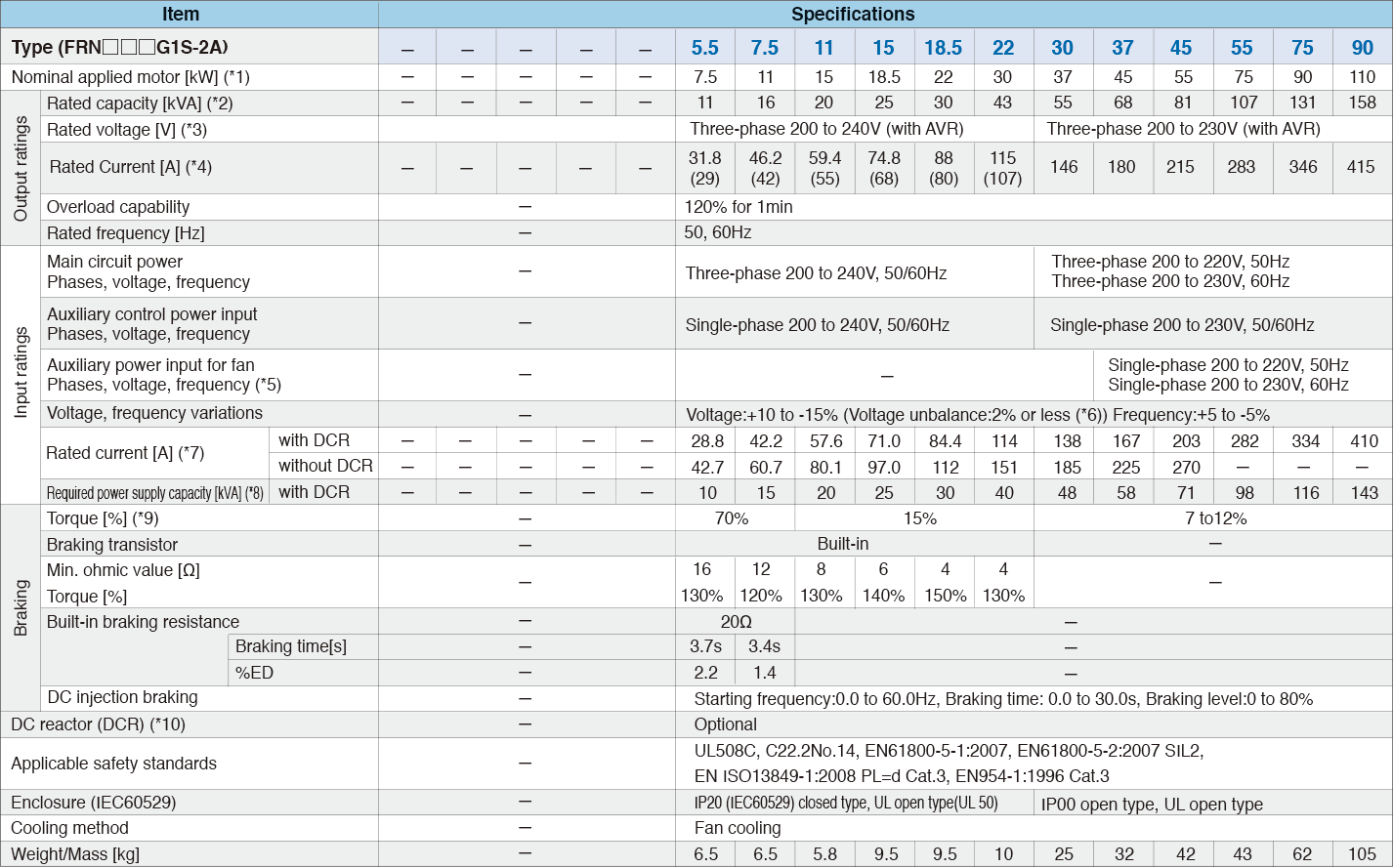

Specification

Three-phase 200V series

HD (High Duty) spec for heavy load

LD (Low Duty) spec for light load

- (*1) Fuji’s 4-pole standard motor

- (*2) Rated capacity is calculated by assuming the output rated voltage as 220V for three-phase 200V series and 440V for three-phase 400V series.

- (*3) Output voltage cannot exceed the power supply voltage.

- (*4) When using the inverter in the ambient temperature of 40℃ or over and with carrier frequency at 3kHz or higher, adjust the current under continuous running to be the value in ( ) or lower by controlling the load.

- (*5) The auxiliary power input is used as an AC fan power input when combining the unit such as high power factor PWM converter with power regenerative function. (Generally not used.)

- (*6) Interphase voltage unbalance ratio[%] = (max. voltage [V] – min. voltage [V])/3-phase average voltage [V]×67(See IEC61800-3.) Use the DC reactor (ACR: optional) when used with 2 to 3 % of unbalance ratio.

- (*7) The value is calculated on assumption that the inverter is connected with a power supply capacity of 500kVA (or 10 times the inverter capacity if the inverter capacity exceeds 50kVA) and %X is 5%.

- (*8) Obtained when a DC reactor (DCR) is used.

- (*9) Average braking torque obtained by use of a motor. (Varies with the efficiency of the motor.)

- (*10) A DC reactor (DCR) is an option. However, Inverters with a capacity of 75kW(HD spec) or above, 55kW(LD spec) or above, require a DCR to be connected. Be sure to connect it to those inverters.

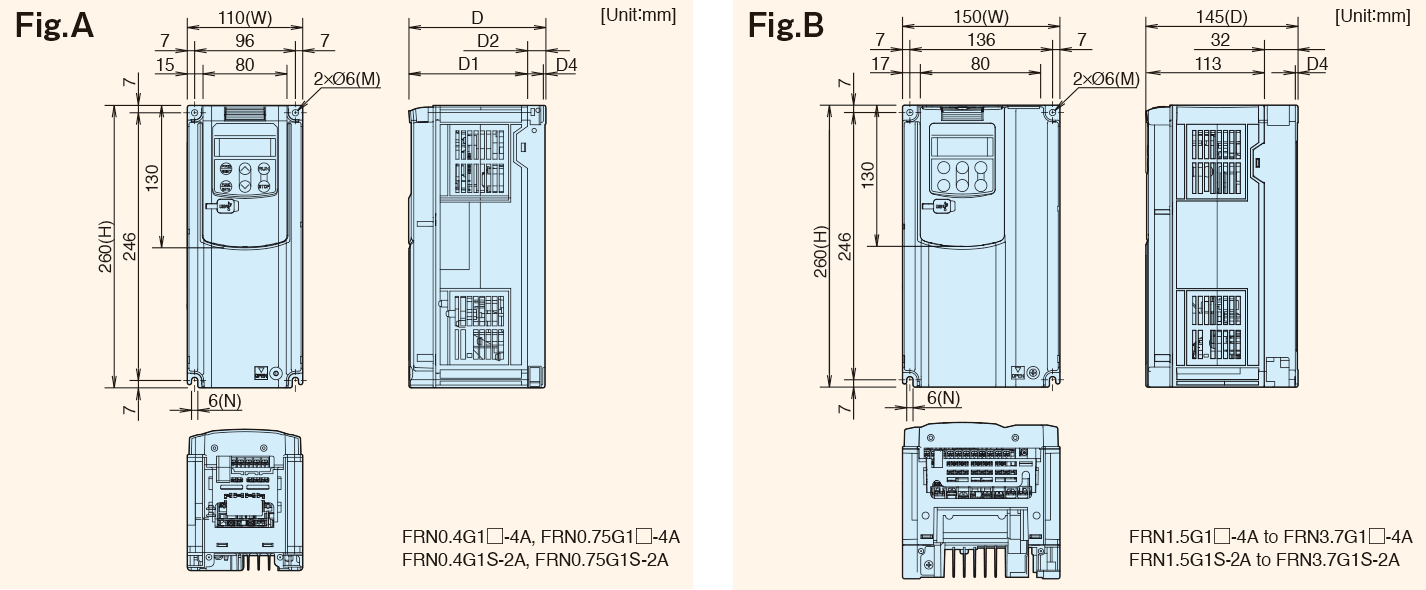

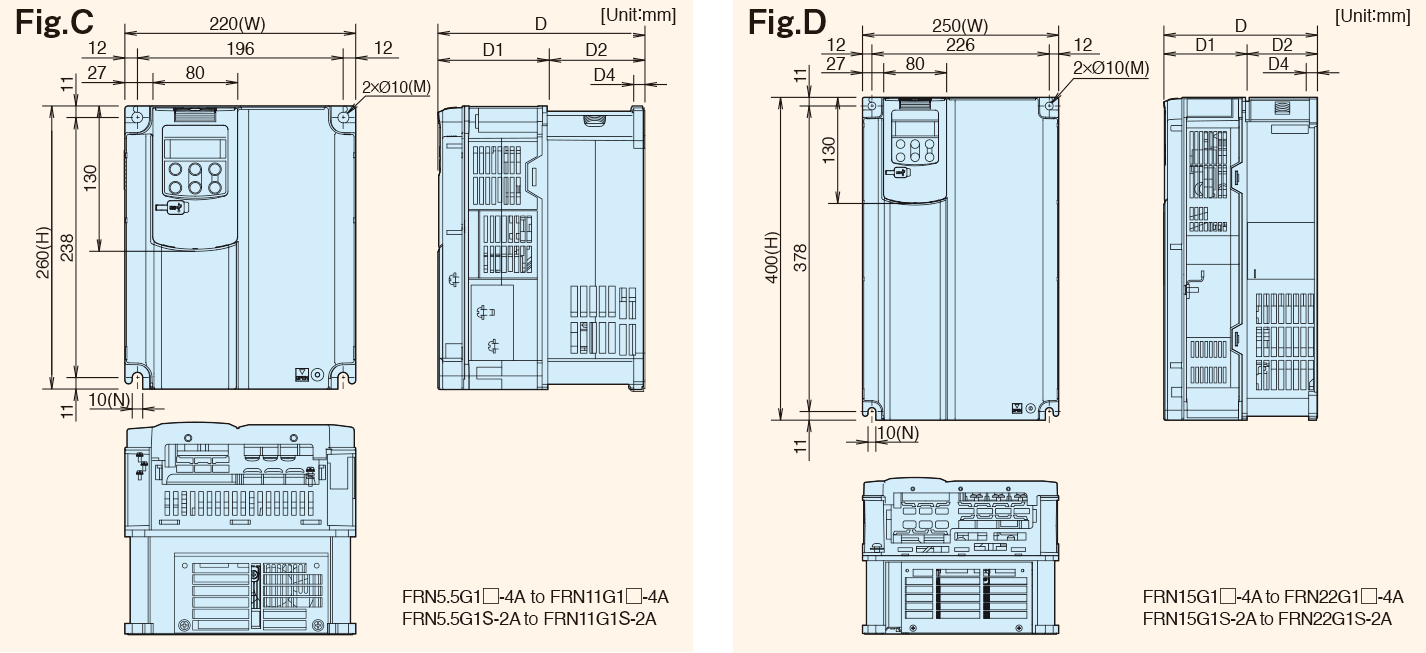

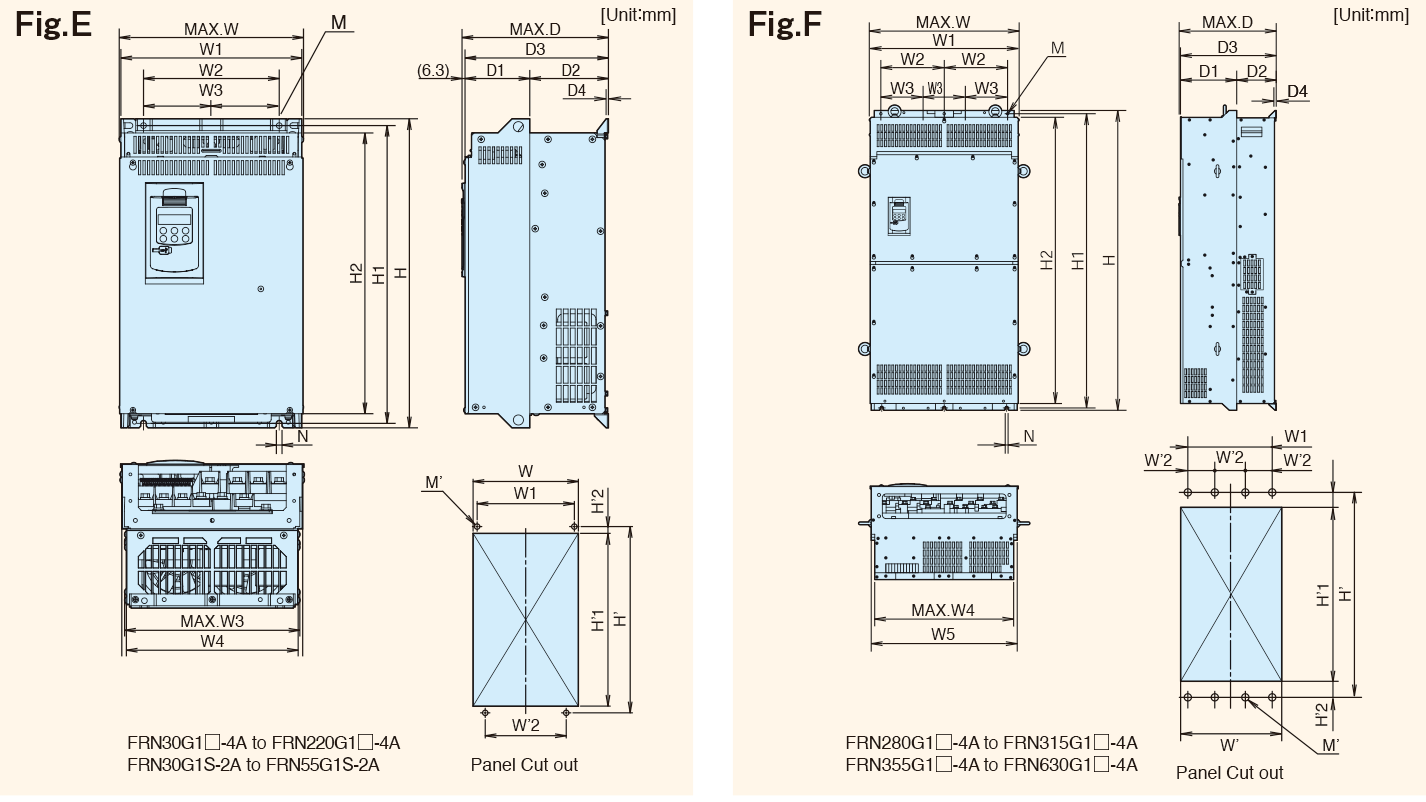

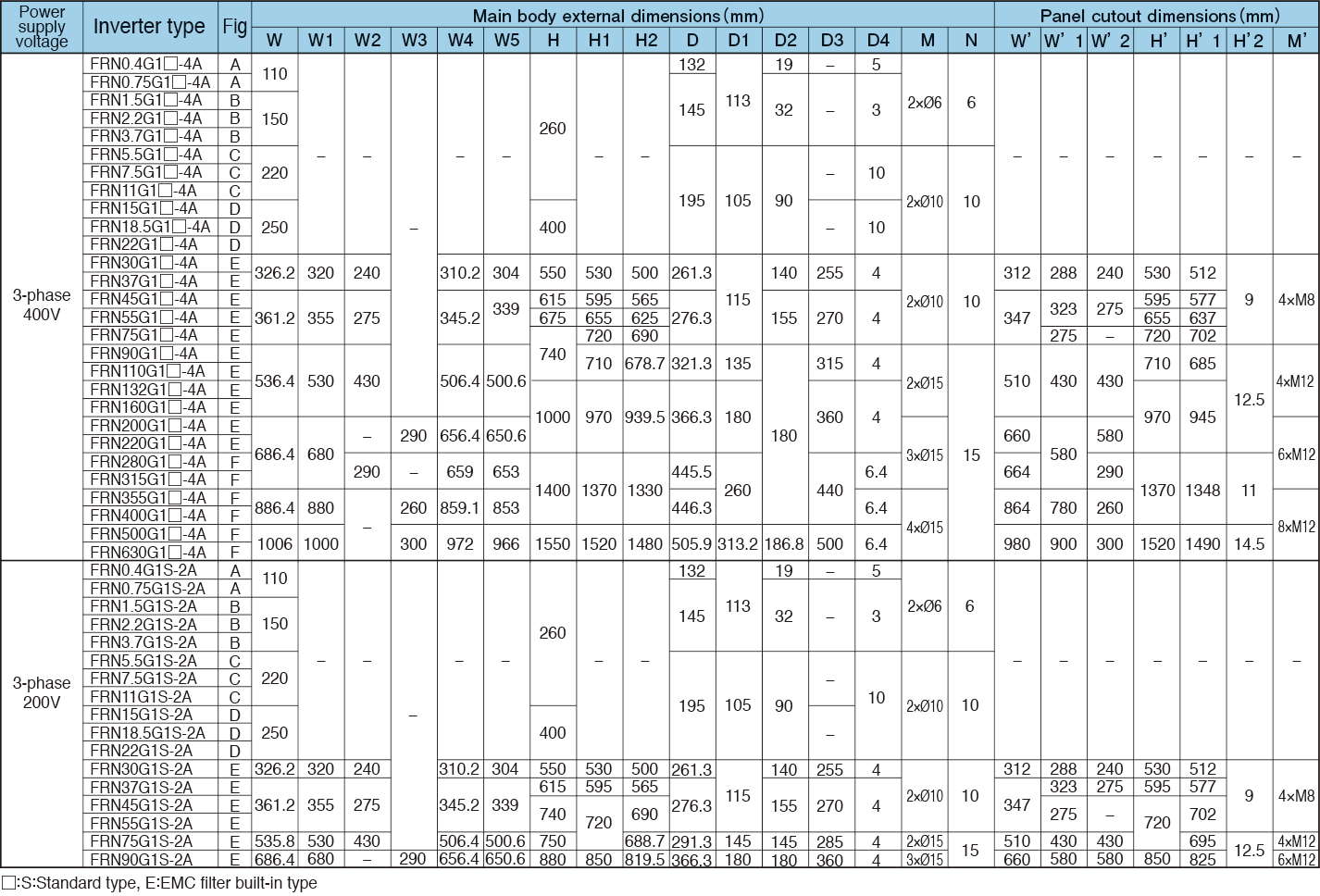

External Dimension

Inverter main body

Basic type, EMC filter built-in type

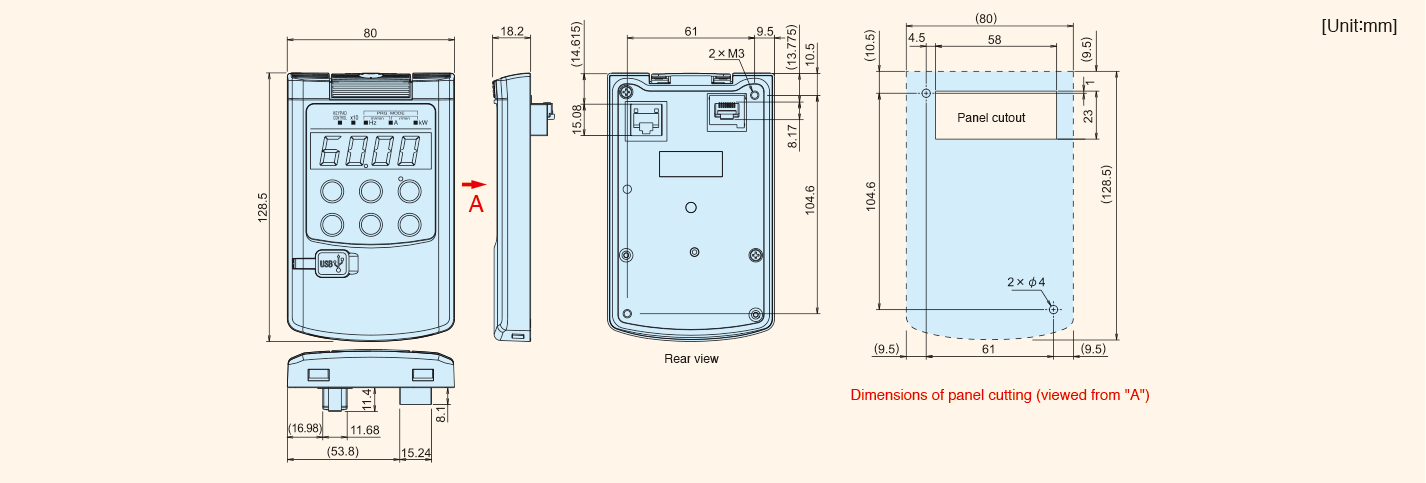

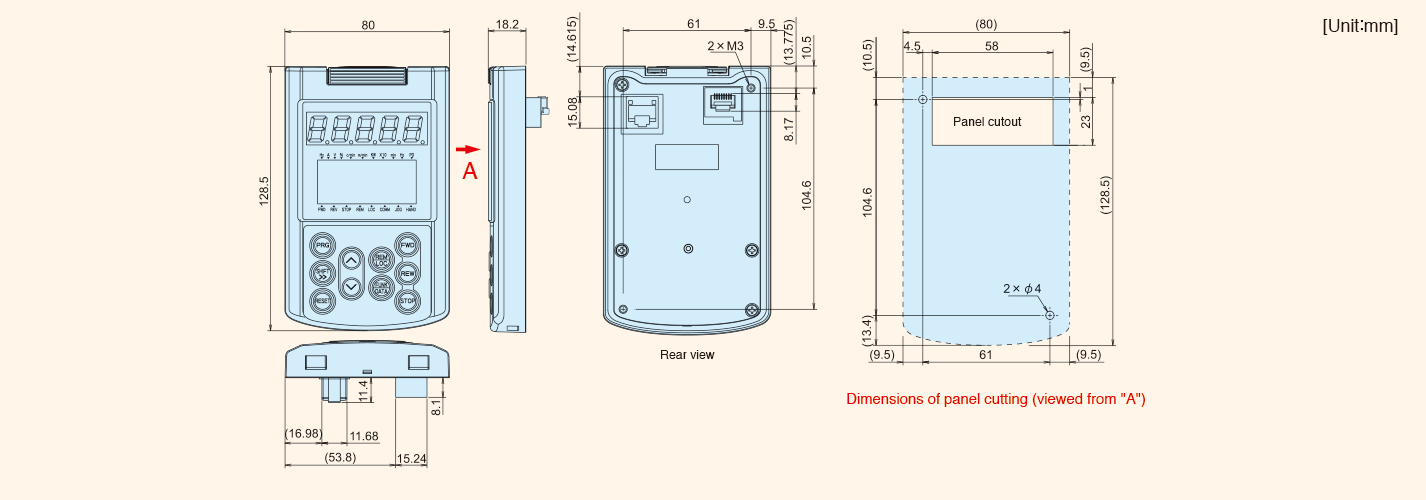

Keypad (Optional)

Keypad (with USB connector model) TP-E1U

Keypad (with USB connector model) TP-E1U

Credit

https://www.fujielectric.com

You must be logged in to post a review.

Reviews

There are no reviews yet.